This product has been developed by utilizing the TÜBİTAK-TEYDEB Support Program (Project No: 3210096). However, all responsibility for the product belongs to Troya Energy Solutions.

We have completed Smokeless Enclosed Ground Flare System manufacturing.

Our enclosed ground flare systems, which differ from conventional flaring in that they don’t produce smoke and minimize noise and visible flame, burn waste gases cleanly and effectively.

Thus, these units are specially utilized in urban areas where continuous open flaring cannot be tolerable.

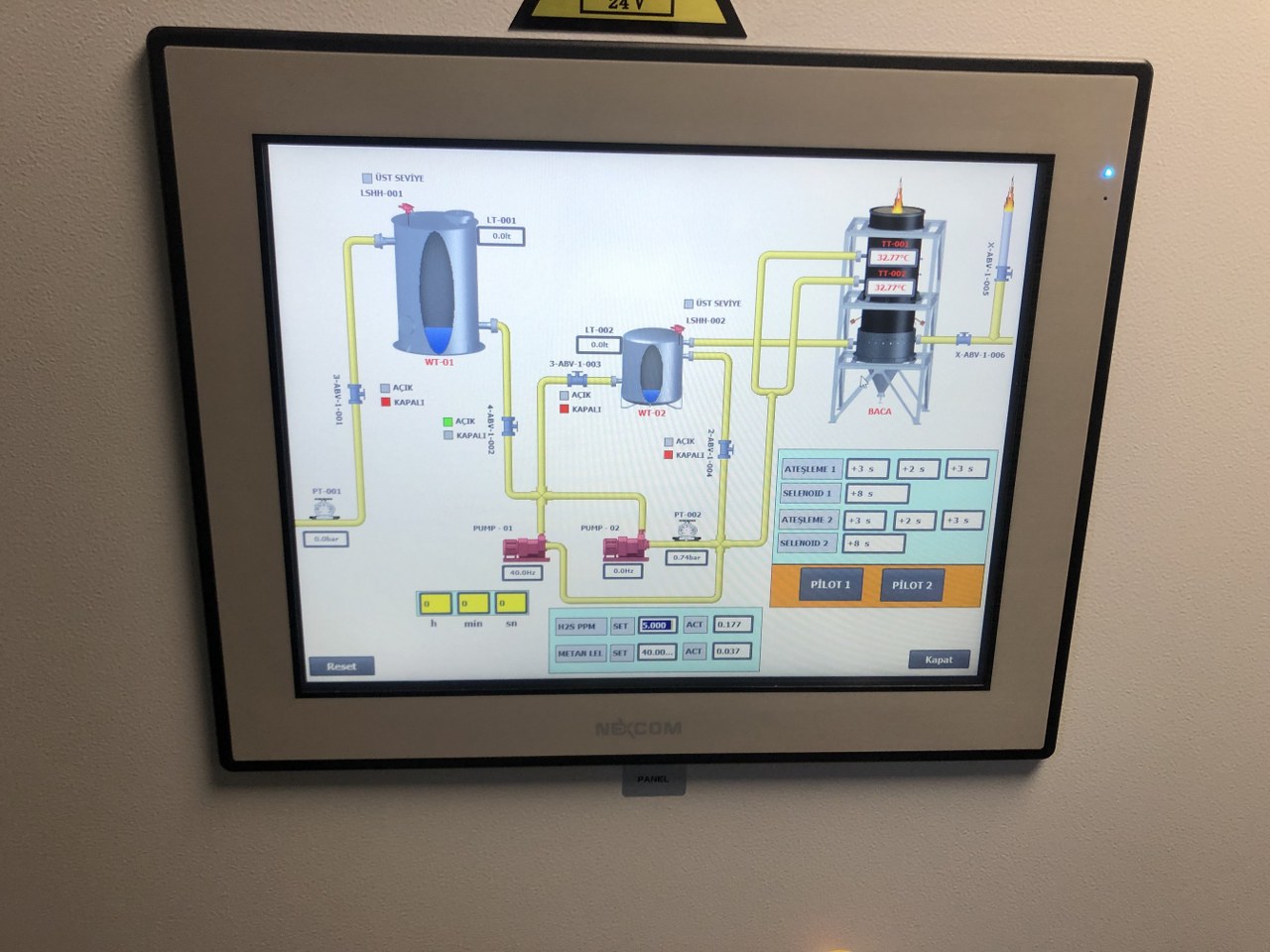

The system consists of two main parts, Flare Skid and Control Container.

The flare skid consists of combustion section, railings and ladder. The combustion section has an outer diameter of approximately 2.3 meters and a length of 7.25 meters. The inner part of combustion area, where the flame occurs, is completely made of stainless steel material, and the outer body that holds whole body is made of carbon steel material. There is a 100 mm insulation material made of ceramic fiber for thermal insulation between the outer shell and the inner shell. The approximate total weight of the skid is 20 tons.

Features:

- High pressure water is used to control smoking.

- The temperature, inside the combustion area, is continuously monitored.

- The water injection system and the combustion area burning quality are controlled by an automation software from the control container.

- Enclosed Ground Flare has 2 waste gas inlet lines, 4” and 3”, to be used according to the gas flow rate.

- There is an automatic ignition system which consists of 2 Pilot Sparkling Units and 1 Control Panel.

- Propane tubes helping the initial ignition and combustion in the flare; moreover, manual and solenoid valves that control the propane sent to the ground flare.

- There are methane and hydrogen sulfide detectors and an alarm panel connected to them to ensure safe operation.